Outstanding people

Uniting science, technology and talent to get ahead of disease together.

Must watch videos (10 videos)

Scroll to explore

Browse our series

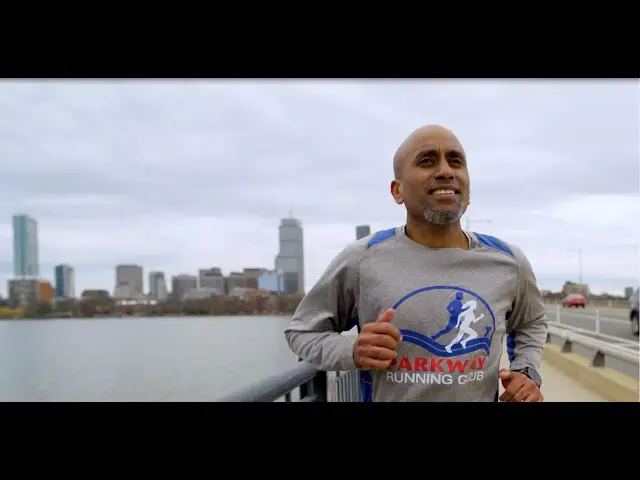

Great place to work (8 videos)

Meet some of the people who make GSK a great place to work.

View series

Latest episode

Meet Richard: tech innovator, future shaper, problem solver, helping us to accelerate our pipeline and performance using advanced technologies.

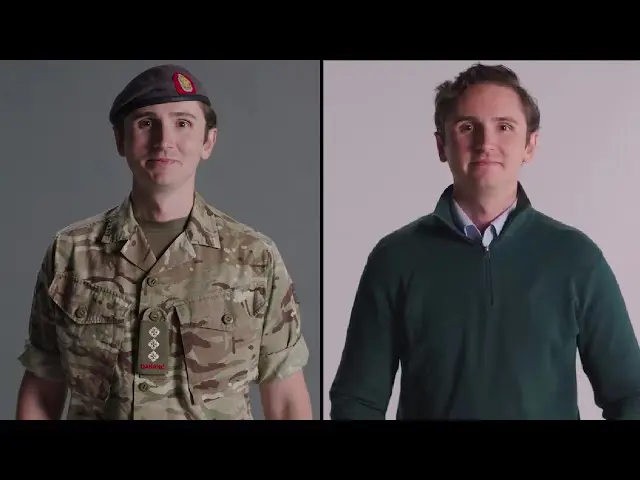

Meet our veterans (4 videos)

Our Veterans bring immense value to GSK and we have a strong commitment to support and mentor service personnel and civil service members as they transition into the corporate environment.

View series

Latest episode

Veterans at GSK

Working together (5 videos)

From inclusion and diversity to sustainability and global health, discover how our people are using their interests and passions to help us get ahead together.

View series

Latest episode

Meet Fiona: improving health and wellbeing through nature

My GSK story (8 videos)

Find out more about the people behind our work, the contribution they make to GSK each day and how they’re embracing our culture.

View series

Latest episode

Meet Dominic: being ambitious for patients

Innovating together (11 videos)

Learn how our people are using the science of the immune system, human genetics and advanced technologies to find new treatments for patients.

View series

Latest episode

Meet Mugdha: working together to help more patients